Your Cart is Empty

How to get the BEST firing results from your kiln

3 min read

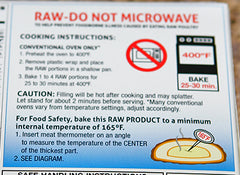

Have you ever noticed the cooking instructions on pre-packaged food products that state; CAUTION: "Appliances vary, these instructions are only a guideline" or "many conventional ovens vary in temperature settings, adjust accordingly"?

Although you will not find this caution on packets of Metal Clay, or in the instruction manual of your kiln, based on my experience, Istrongly recommend keeping this caution in mind when working with different metal clay.

In fact, I would go so far as to say that even without a change in the type of metal clay being used, you should always be prepared to adjust your firing schedule to your location. Even changing your kiln from room to room could have an influence on its' performance.

One of the questions I receive the most often from those looking to start working with metal clay is "what type of kiln do you use?" (the #1 question is "do you recommend torch firing MC ?" - find the answer here).

Of course, if my "Little Blue Temple of the Goddess of Fire" works for me, then obviously it will produce the same result for you! Right?

Unfortunately, like the caution for food products, we need to consider not only the "oven" (kiln) but also the location it is being used in. For example, when I started working with metal clay, I was living in Montreal (Canada). A location that has a variation in climate temperature from an average -5° in winter to +26° (C) in summer along with a very high humidity index. It would be unreasonable to expect that a kiln is not influenced by such dramatic atmospheric elements. If you live in a climate that experiences extremes in climate maybe add a barometer to your studio?

Keep a firing log that includes:

-

the material you used along with the brand name,

-

the amount (approx. weight),

-

the number of pieces,

-

the firing schedule,

-

the end result.

Your log will be an important tool that will help to reduce "catastrophic failure" of projects along with providing insight into the variations in the color of metals that can be achieved. If you fire gemstones in place (although we do not recommend this!), your firing log will also help to determine the potential color changes of the gemstones.

It will most importantly, provide you with YOUR firing schedules for YOUR kiln in YOUR location.

Be consistent in the products you use:

Keep a note of all the products you use including even the cleaner you use for your work surfaces and tools. For example after many hours of troubleshooting the firing failure of some CoppR Clay pieces, I realized that I had used "Slik Balm" to lubricate my surfaces, tools and hands.

This is why I only use olive oil, it has never negatively impacted any metal clay to date.

Test fire after changing any firing related equipment, stainless pan, shelves, carbon etc. The core message, test fire before firing projects that you have invested a great amount of creative energy!

Follow this advise and you will learn from YOUR experience and increase your understanding of working with metal clay. Alternatively, you could post a question in a metal clay forum and spend hours trying to understand why so many people with great intentions to help can have such a variation in replies. Then make another post to determine which answer fits your situation.

Please feel free to leave examples of your firing failures and resolution experiences in the comments, that can really help others along their creative paths.

Leave a comment

Comments will be approved before showing up.